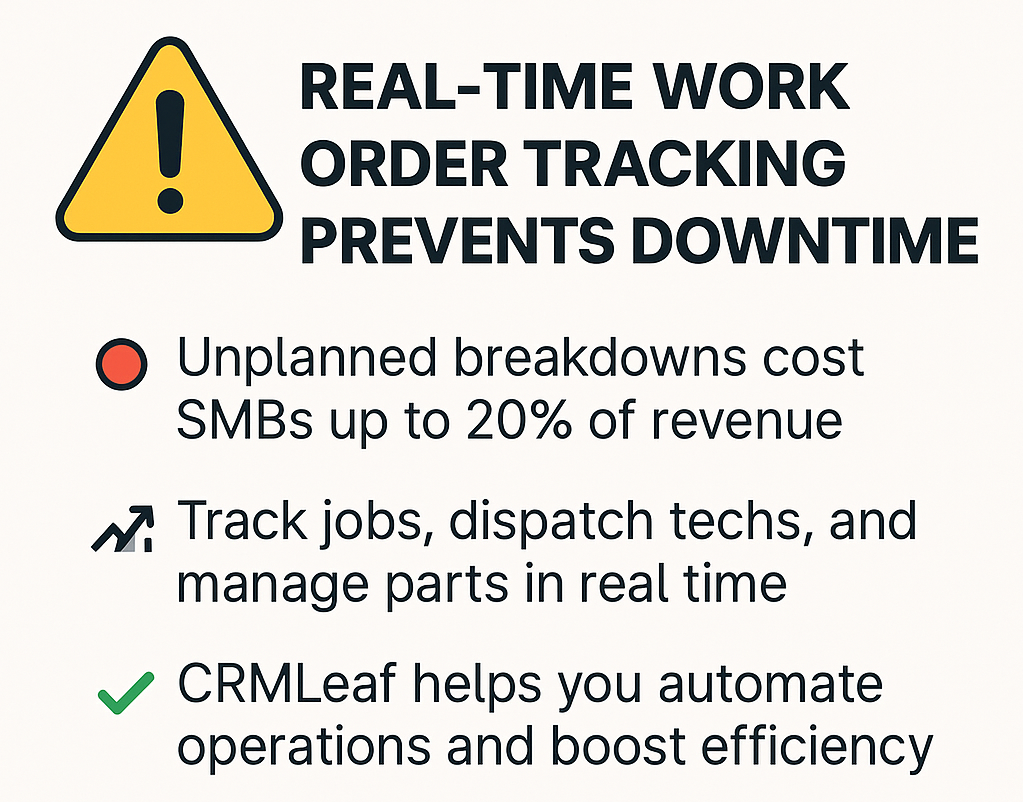

In today’s fast-paced market, unplanned equipment breakdowns and delayed service calls can cost SMBs up to 20% of their annual revenue. If you’re still juggling spreadsheets, sticky notes, and disconnected solutions, you’re inviting downtime and disappointed customers. With an integrated customer relationship management software and ERP platform, you can transform chaos into clarity — automatically capturing work order updates, dispatching technicians, and tracking parts in real time.

In this post, you’ll learn how real-time work order tracking reduces downtime, slashes labor costs, and elevates customer satisfaction. We’ll explore the business case, best practices, and actionable tips — plus a hypothetical success story — to show why CRMLeaf is your trusted partner for end-to-end operations management.

Business Need & Importance

As businesses grow, so does the complexity of coordinating field service, inventory, and customer expectations. CRMLeaf’s CRM + ERP platform solves this by unifying every stage of the service lifecycle — right from the customer call to the final invoice. Here’s why real-time work order tracking within your customer relationship management software matters:

Minimizing Idle Time

When field teams aren’t instantly updated on new tasks or status changes, they waste time waiting for dispatchers or hunting for parts. Real-time tracking ensures every technician knows exactly where to go and what to do next — eliminating guesswork and bench time.

Boosting First-Time Fix Rates

By integrating your document management system and parts inventory, technicians arrive fully equipped. No more return visits because of missing components. First-time fixes translate into happier customers and reduced labor expenses.

Enhancing Customer Transparency

Today’s end-users demand immediate updates. A linked customer relationship management software module sends automatic SMS or email alerts when jobs are assigned, in progress, or completed — building trust and improving your Net Promoter Score (NPS).

Streamlining Compliance & Audits

For industries like healthcare, manufacturing, and utilities, accurate service logs are mandatory. Automated time stamps, digital signatures, and geo-tags stored in a document control software ensure you’re always audit-ready.

Real-time work order tracking is critical across multiple verticals:

- Manufacturing: Keep production lines running by prioritizing repair orders.

- Facilities Management: Coordinate janitorial, HVAC, and security tasks on a single dashboard.

- Telecommunications: Dispatch field engineers with live network status updates.

By centralizing operations in one CRM + ERP solution with built-in customer relationship management software, you gain visibility and agility — essential ingredients for sustainable growth.

Best Practices & Actionable Tips

Ready to implement real-time work order tracking? Follow these best practices to maximize ROI and minimize downtime:

1. Establish a Unified Data Backbone

Standardize Terminology & Processes

Define clear work order statuses —“Scheduled,” “In Progress,” “Awaiting Parts,” “Completed”—so every team speaks the same language. This consistency prevents miscommunication between dispatchers, technicians, and managers.

Integrate with Human Resource Management Software

Sync work orders with employee profiles to automatically assign tasks based on skill sets, certifications, and availability tracked in your all in one HR software.

2. Leverage Mobile-First Workflows

Deploy a Field Service Mobile App

Empower technicians with offline access to work orders, service history, and parts catalogs. An intuitive mobile interface reduces data-entry errors and speeds up job completion.

Automate Photo & Signature Capture

Require field staff to snap before-and-after images or collect customer signatures. These artifacts feed directly into your document management or legal document management software, ensuring compliance.

3. Implement Proactive Notifications

Real-Time Dispatch Alerts

Use geofencing and live location data to automatically notify the nearest qualified technician when a high-priority work order is created. This cuts response times dramatically.

Customer Alerts & Feedback Loops

Send automated SMS or email updates when the technician is en route or job status changes. Immediately request feedback upon completion to close the quality loop.

4. Optimize Inventory & Parts Management

Real-Time Inventory Sync

Integrate your document management system with parts warehouses to display accurate stock levels. Low-stock triggers should auto-generate purchase orders or alert warehouse managers.

Bill of Materials (BOM) Templates

Predefine BOM for common repairs. When a work order is generated, the system auto-populates required parts — reducing manual selection errors and restock delays.

5. Analyze, Refine, Repeat

Work Order Performance Dashboards

Track KPIs like average response time, mean time to repair (MTTR), and technician utilization. Use these insights to reassign resources or retrain staff.

Continuous Improvement Workshops

Hold quarterly reviews with cross-functional teams — operations, customer service, HR, and finance — to identify bottlenecks. Feed learnings back into process updates in your human resource management systems.

By adopting these practices within a unified CRM systems framework powered by customer relationship management software, you eliminate data silos, ensure accountability, and drastically reduce unplanned downtime.

Customer Success Story: Apex Industrial Services

Apex Industrial Services, a mid-sized manufacturing company, leveraged CRMLeaf’s real-time work order tracking to overhaul their field service operations. Before CRMLeaf, Apex relied on paper tickets and separate spreadsheets — resulting in average response times of 4.8 hours and a first-time fix rate of just 62%.

Within three months of implementation:

- Response Time ↓ 45%

Automated dispatch and mobile alerts cut average response from 4.8 to 2.6 hours.

- First-Time Fix Rate ↑ 30%

Integrated parts inventory and BOM templates ensured technicians arrived fully equipped.

- Downtime Costs ↓ 28%

With production lines back online faster, Apex saved nearly $75,000 in lost output.

“CRMLeaf transformed our service delivery,” says Operations Director Maria Lee. “The visibility and automation not only improved customer satisfaction but also freed our back-office teams from manual data entry.”

Key Takeaways: CRM + ERP Meets Real-Time Field Service

Real-time work order tracking isn’t just a nice-to-have — it’s a strategic imperative for SMBs aiming to outpace competition. By centralizing dispatch, mobile field tools, inventory sync, and customer notifications within a single customer relationship management software platform, you’ll:

- Slash unplanned downtime and labor costs

- Boost first-time fix rates and customer satisfaction

- Maintain audit-ready records with built-in document control software

At CRMLeaf, we provide an end-to-end CRM + ERP solution that ties together attendance software, payroll services for small business, online payroll services, and service management — eliminating data silos and driving efficiency across your entire organization.